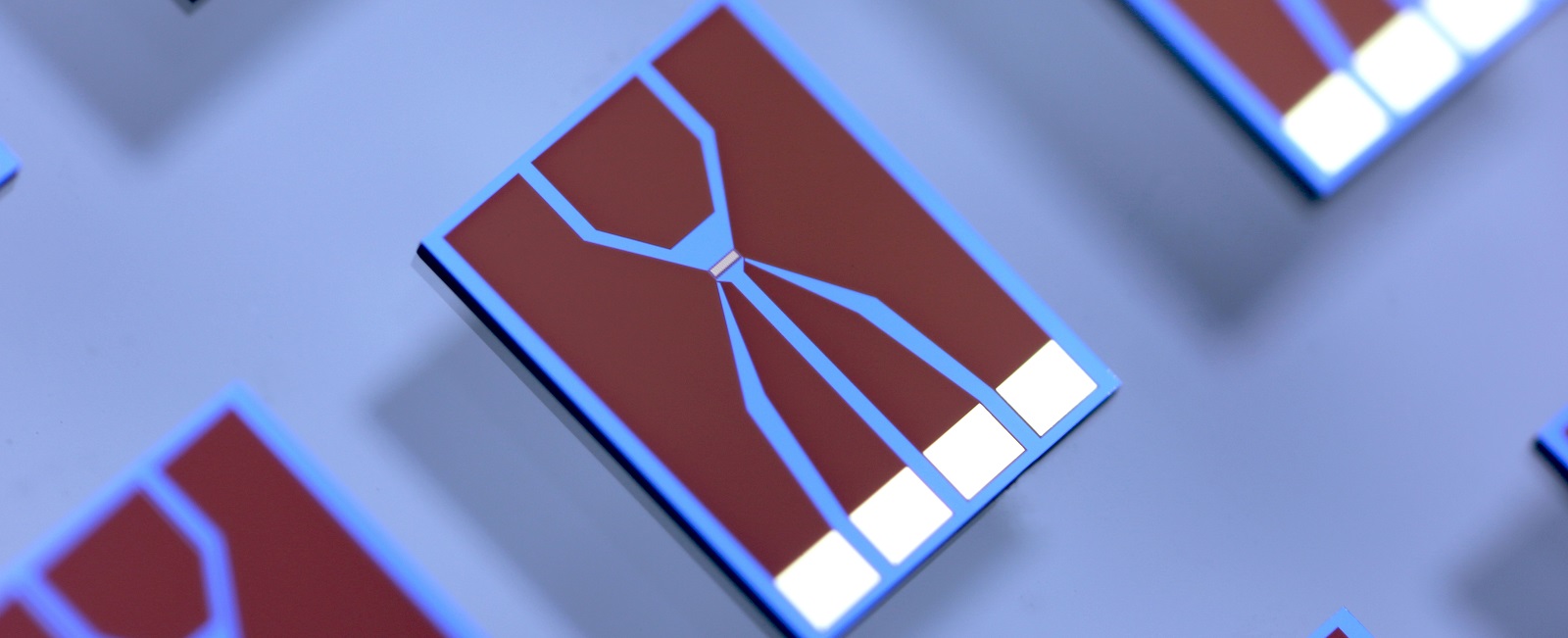

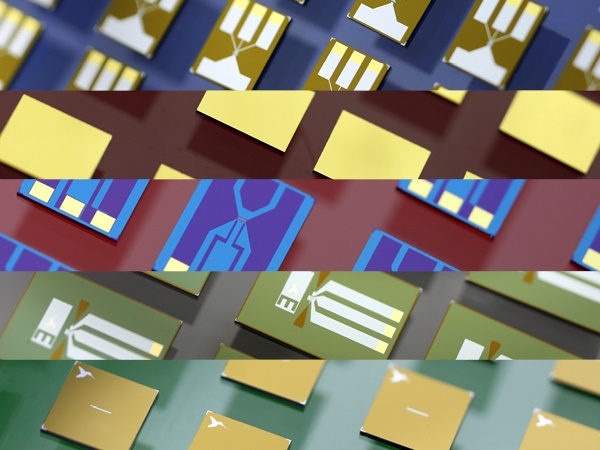

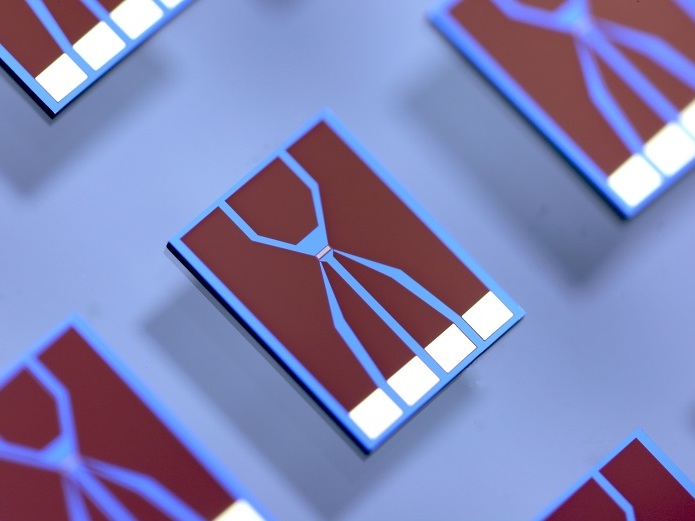

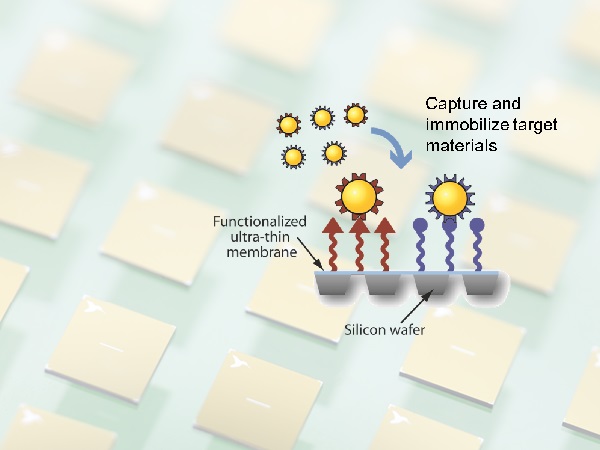

Hummingbird Scientific’s microfabrication division provides chips and microfabricated devices for a broad range of in-situ TEM, SEM, X-ray and optical microscopy applications. The primary role of the microfabrication division is to support users of our in-situ specimen holders, and with that in mind, we have developed a full line of chips for our gas, liquid, heating, and electrical biasing holders. The division can also provide custom chips and device design services for other applications.

Our team of scientists, engineers, and technicians have extensive experience in advanced semiconductor device design, processing, and inspection. Together we are re-imagining the in-situ experiments that are possible inside your microscope.

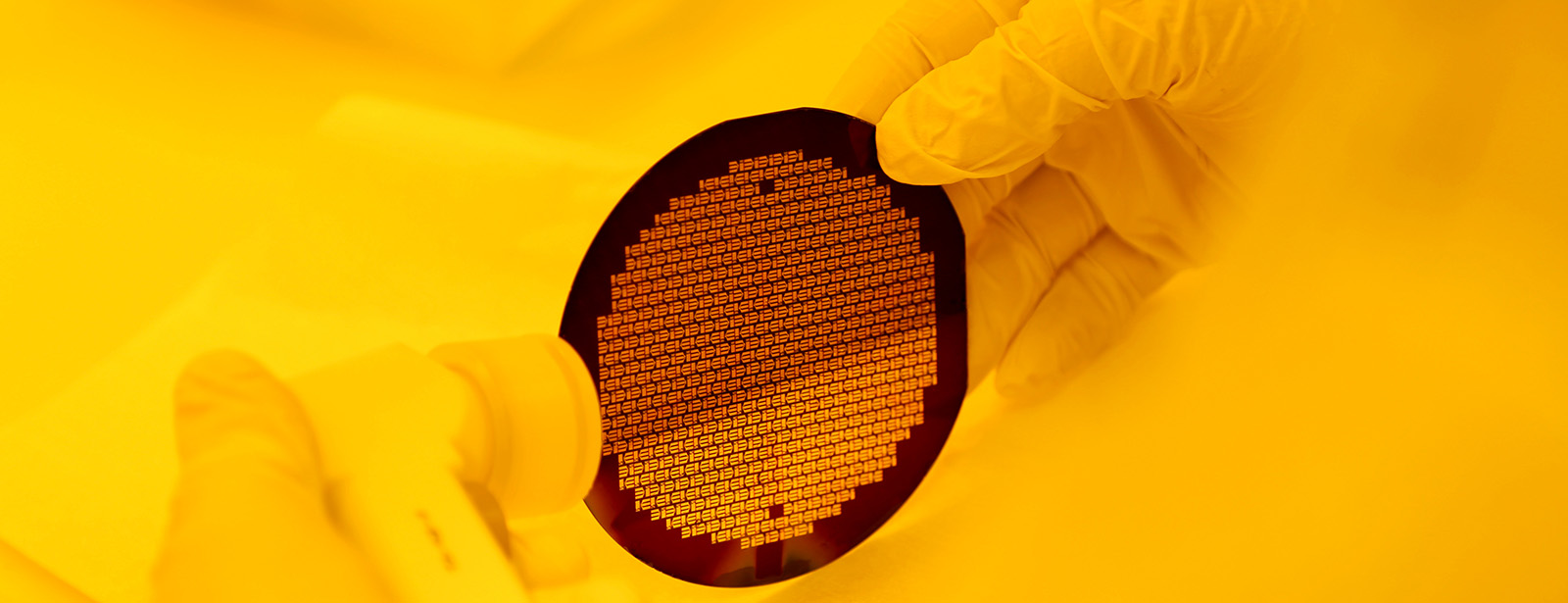

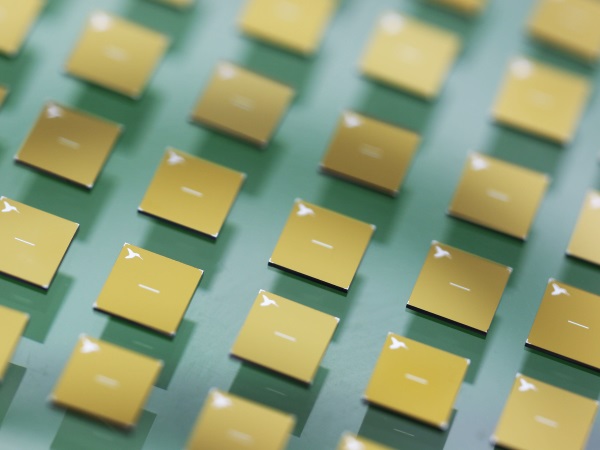

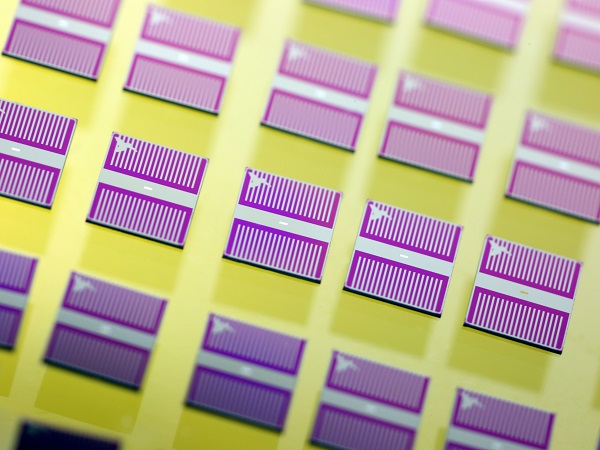

Wafers are inspected throughout the fabrication process to ensure that they adhere to all specifications. In post-processing, all chips are subjected to our rigorous proprietary chip cleaning process. They are then individually inspected for dimensional accuracy and cleanliness. Finally, they are packed in clean room conditions and remained sealed until they reach the user’s lab.

To help keep the chips as clean as possible once they reach your lab, we include chip-handling protocols as part of on-site product training. These processes help users maintain the cleanest and highest-quality chips and thus the best sample and imaging conditions in the microscope.

Hummingbird Scientific has a web store for users of our liquid, gas, heating and electrical biasing holders. Do you have one of these holders? Once your account has been created, you’ll be able to browse our wide array of microfabricated chips and accessories and find detailed information about all our chip configurations, all with the click of a button. You’ll also be able to order custom chips online.

Optimized for an easy shopping experience, our web store is designed to get you the microfabricated technology you need, when you need it